The 5G-VICTORI consortium concluded on June 27th in Patras, Greece, its ultimate Field Trials and, as the last event of...

UC #2: Factories of the Future

The main objective of this UC is to automate the monitoring process and improve inspection methods and maintenance procedures of energy utilities as Factories of the Future, both for cost/time reduction and quality improvement. The idea is to showcase how 5G technology can integrate and deliver services able to support these diverse applications simultaneously.

These services are mainly grouped into three classes: maintenance, security and operation services. Maintenance activities require support of low cost, energy efficient sensors, planted in a distributed and heterogeneous infrastructure. Security and operation services ask for low latency trip signals and high bandwidth for CCTV. More specifically, three different scenarios will be demonstrated:

- The application of mMTC-banded IoT architectures for preventive maintenance and monitoring of the factory assets.

- The support of uRLLC-type applications for real time monitoring and automation in an industrial environment.

- The provision of eMBB services for smart CCTV surveillance applications.

5G-VICTORI Patras Facility

The baseline implementation of the Patras 5G-VICTORI experimental platform is being developed within the ICT-17 5G-VINNI project. The plan in 5G-VICTORI is to upgrade this platform with additional functionalities and to extend it towards several operational facilities owned by Greek vertical industries. This will allow the implementation of the 5G-VICTORI UCs running in Patras, and will be able to also support cross-vertical and cross-facility experimentation and KPIs validation. In this regard, different 5G service classes will be supported, i.e. eMBB, uRLLC and mMTC.

Developed solution

The deployment of the new infrastructure brought by the 5G-VICTORI project involves installation of sensing devices at the predefined locations and powered through either battery/solar cells or connected to the power supplies provided by ADMIE (Figure 1). The cells providing the gateway of the collected data are installed (software defined NB-IoT cell, COTS LoRaWAN gateway, Wi-Fi AP) along with the edge data centre and the remote connection to the 5G-VINNI facility.

Figure 1 shows the placement area that was selected for the demo following initial site surveys between the Rio (B1) and Antirio (B2) terminal stations. Indoor installations have already been performed in B1, however a major power cut need to be planned in order to perform the outdoor installations of the antennas.

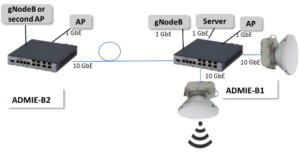

Figure 2 shows the final network deployment and network installations equipment that is needed to ensure that the UC can be executed and that the KPIs are guaranteed. The two sites are directly interconnected via a fibre link, which is terminated at B1, where both the gNodeB and the edge processing units are based. At B2 gNodeB is not necessarily installed as the data volume and the trails discussed do not justify 5G radio, however architecturally the design can support an extra gNodeB at B2 if necessary. Both AP shown in the figure are considered Wi-Fi and gateways are interconnected via these AP. Also CPEs (see introduction) are used for the collection of data from the various sensors. The fibre link terminates at the edge processing unit where part of the two layer architecture is deployed and part of the platform is hosted. Then backhauling is performed via the mmWave links to the UoP premises.

Service Deployment

To support the Smart Factory services, where each one of them imposes a substantially different set of KPIs, QoS mechanisms and schemes to the overall architecture, three dedicated slices are going to be instantiated concurrently on the network. Each slice corresponds to a different service:

- A slice responsible for the timely collection of HV power cable sensor data from the two ADMIE sites at Rio and Antirio

- An eMBB slice for providing high-bandwidth communications to address sensor data collection, fusion and storage to the cloud

- An eMBB slice for providing high-quality live video streaming dedicated to smart facility monitoring and inspection.

Partners

Related news

Field Trials and Workshop in Greece mark the final milestone for the 5G-VICTORI Project

The 5G-VICTORI consortium will gather in Patras and Athens from Monday, June 26th, to Wednesday, June 28th, to conduct their...

ADMIE contribution to 5G-VICTORI’s UC # 2: “Digitization of Power Plants”

The main objective of the “Digitization of Power Plants” Use Case is to extend the capabilities of the Patras 5G-VINNI...